|

Shock and Vibration Systems

|

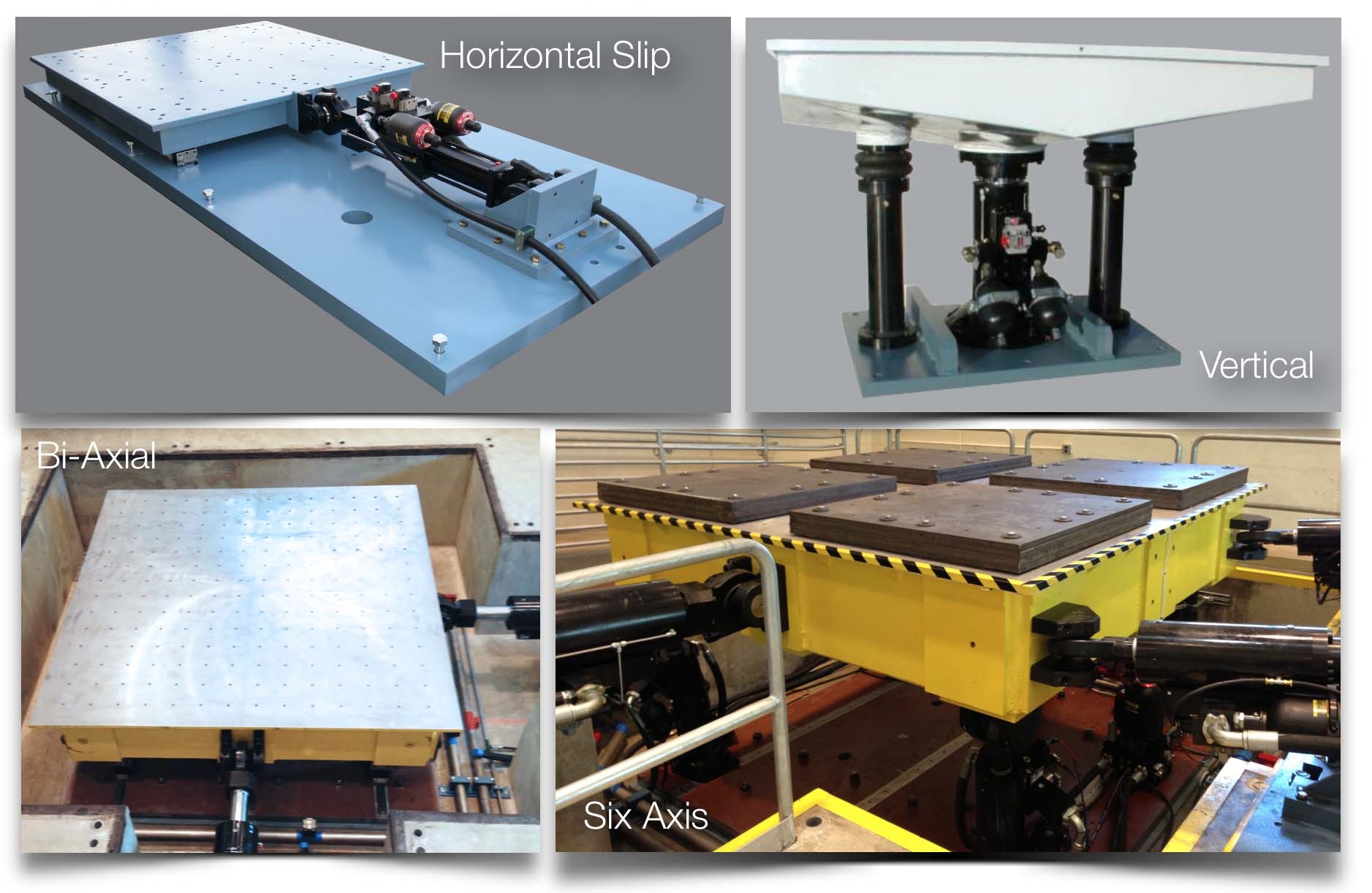

Specimens whose failure is a direct result of vibration are usually tested on vibration tables. Rough roads, earthquakes, shaped random, shock or sine sweep signals are used to replicate the service environment. Because the specimen reacts the loads inertially, there are fewer concerns with boundary conditions. As long as the specimen is well fixtured, and the vibration is accurately simulated, the laboratory test is very representative of the operating environment.

Our Real Time Active Control (RTAC) technology is used in combination with our well engineered light and stiff tables to provide high accuracy simulation in any number of degrees of freedom.

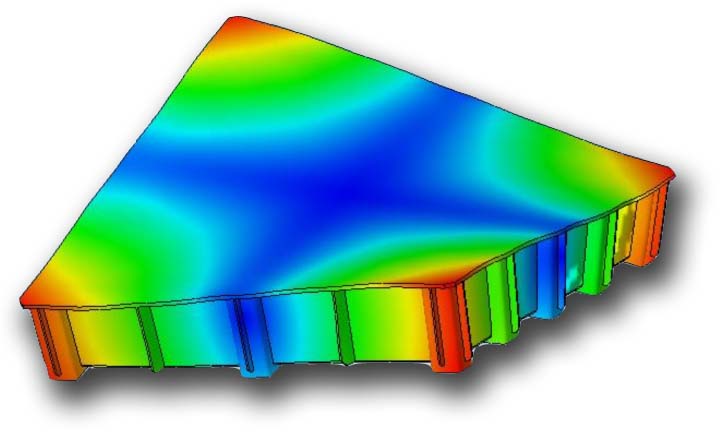

Our engineers use design analysis tools to maximize stiffness and minimize weight. The material and manufacturing methods are selected based on the table size and the number of degrees of freedom. We build monolithic aluminum tables up to 1.5mx1.5m (60"x60"), and welded aluminum tables up to 3mx3m (120"x120"). Larger tables are manufactured from welded steel, and in special cases, we have even built tables from magnesium. Constructed as a hollow webbed design, the 3mx3m table structures have high first-mode natural frequencies in excess of 160Hz.

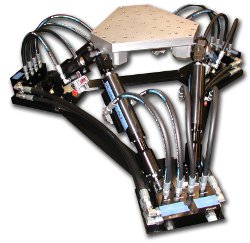

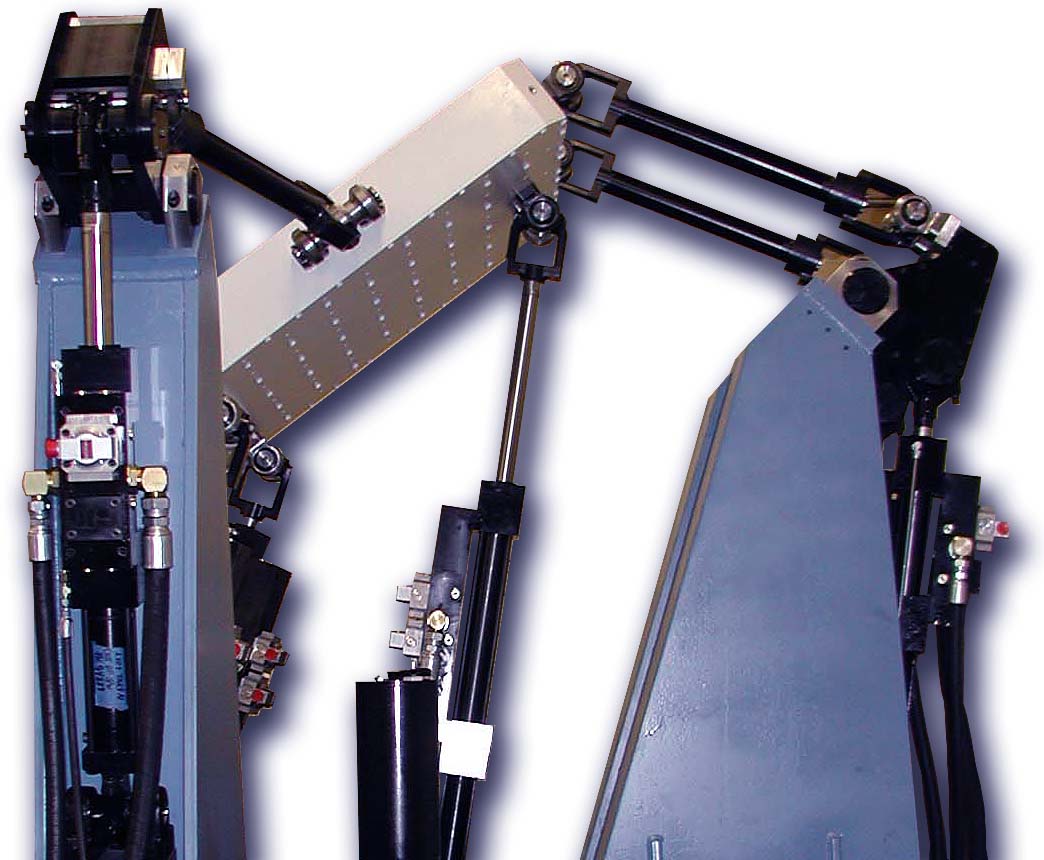

Six degrees of freedom tables can be configured for installations in an enclosed pit, with strong-back reaction, or with bell cranks.

For higher frequency operation, hexapod tables provide a solution with a small compact footprint and shorter struts. BIA West builds hexapod tables in a range of sizes.

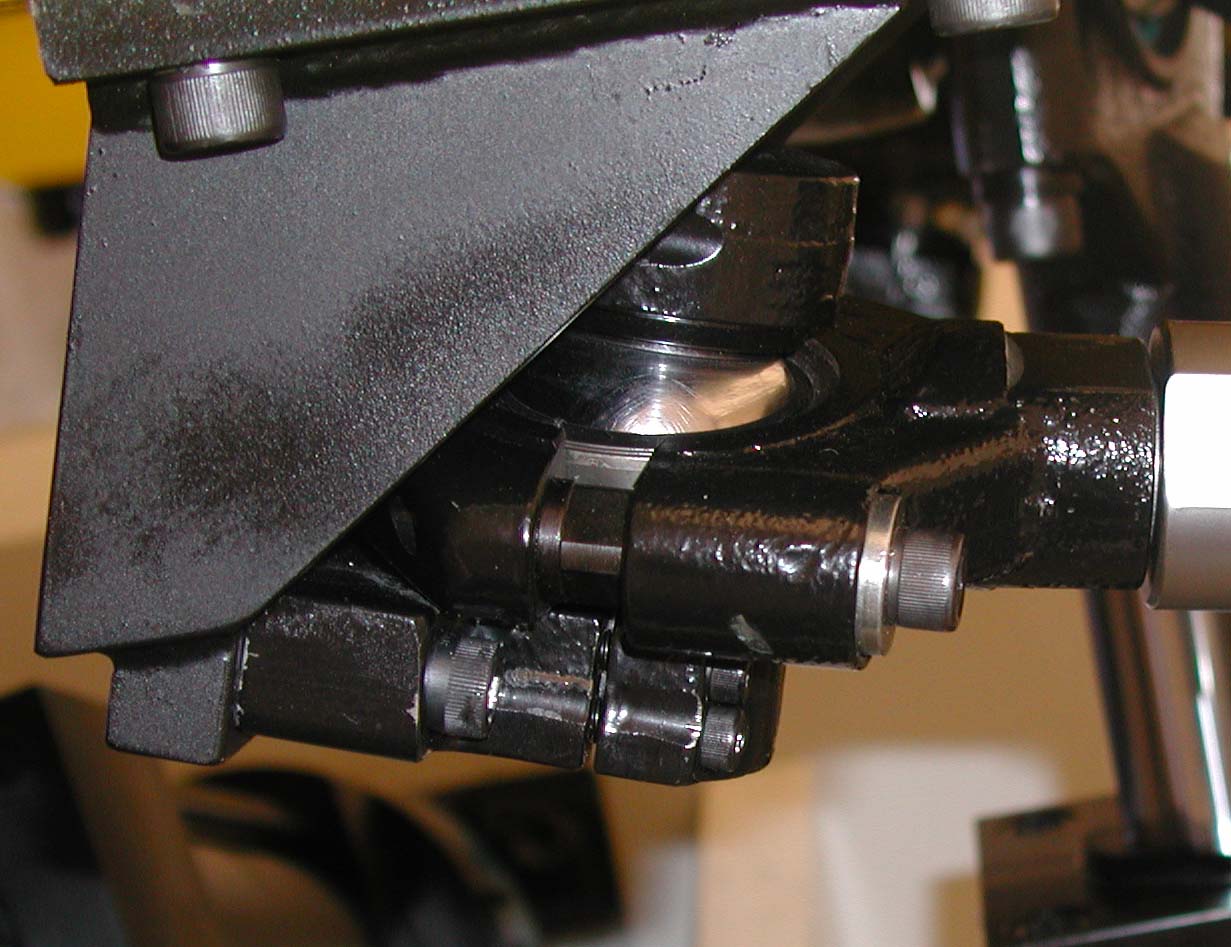

BIA West is the only company that can provide many swivel options. Standard swivels are the least expensive, and are used in the majority of our tables. They are castings with pre-loadable bearings. These types of bearings are very common, and are used for most applications.

For very high angle requirements, BIA West can create double cardan joints that can articulate up to 90 degrees.

For applications that require a swivel with equal angle in all directions, BIA West uses a ball swivel. These can utilize standard teflon bearings, or when friction is an issue or for very high loads, we can build hydrostatic bearings.

The actuator sizes and servo valve combinations are selected so that the performance envelope of your table can be tailored to meet your specific and unique needs.

If you want to use your table to perform random vibration, sine sweep classic shock or SRS tests, we partner with reputable companies who can provide this capability so that you get a complete, turn-key solution to your needs.